Capabilities

manufactures products to the highest possible value on a wide range of materials such as Inconel, High Nickel Alloys, Carbon Steels, Stainless, Monel, Hastalloy, Titanium, Beryllium Copper, Brass, Bronze to mention a few.

manufactures products to the highest possible value on a wide range of materials such as Inconel, High Nickel Alloys, Carbon Steels, Stainless, Monel, Hastalloy, Titanium, Beryllium Copper, Brass, Bronze to mention a few.Turn-Tech’s 40,000 lb. (20 ton) overhead crane’s capacity makes handling heavy materials and parts a safe process for loading machines and trucks.

With our state-of-the-art machining capabilities and skilled craftsmen, Turn-Tech is capable of producing a wide variety of components from simple to complex geometry. Turn-Tech uses MasterCam, Shop-Talk, and WinMax for their CNC programming. These programs are some of the leading and most versatile CAD/CAM systems in the industry assisting Turn-Tech in meeting your machining requirements and Turn-Tech’s Quality standards.

Turn-Tech, Inc. maintains quality committed vendors over the years for material, heat treating, welding, non-destructive testing, coating, plating, and all other special processes making Turn-Tech a turn-key supplier of machined parts and assemblies with a “Total Commitment to Quality and Customer Satisfaction.”

Turn-Tech, Inc., with its many years of experience and excellence, monitors product quality from raw materials to shipped finished products.

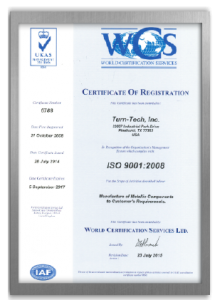

Turn-Tech, Inc. is certified to ISO by World Certification Services. Maintaining ISO certification requires continuous training in order to meet the requirements and demands of the certification registrar. Since 1995, ISO Certification has assisted Turn-Tech, Inc. to continually improve its quality objectives.

Maintaining ISO certification requires continuous training in order to meet the requirements and demands of the certification registrar. Since 1995, ISO Certification has assisted Turn-Tech, Inc. to continually improve its quality objectives.

Turn-Tech, Inc. has received customer’s highest rankings for Quality and On-Time Delivery. This is possible because of the Total Commitment of the Turn-Tech Team to Quality, On Time Delivery and Total Customer Satisfaction.

![]() Turn-Tech uses JobBOSS Shop Management Software for bidding, order processing, scheduling, purchasing, shipping and accounting. The tracking and Bar Coding System is recognized as one of the top shop management programs. This system assists Turn-Tech in maintaining quality and traceability throughout its processes.

Turn-Tech uses JobBOSS Shop Management Software for bidding, order processing, scheduling, purchasing, shipping and accounting. The tracking and Bar Coding System is recognized as one of the top shop management programs. This system assists Turn-Tech in maintaining quality and traceability throughout its processes.

Turn-Tech’s ownership and top management are available to our customers to provide Total Commitment to Quality and Customer-Satisfaction.

WE TEACH “QUALITY CANNOT BE INSPECTED INTO A PART!”

Machined parts must be processed and manufactured correctly by highly-trained personnel with quality manufacturing processes and equipment, using calibrated measuring tools and gauges, and then it’s verified by our skilled inspection department. Therefore, Turn-Tech verifies its quality manufacturing by using up-to-date and precision measuring equipment such as CMM, digital height gauges, comparator, calibrated gauges and all other essential inspection equipment. Our quality trained personnel ensures that the company’s quality policies are met which meets or exceeds customer requirements and expectations.